website watertownhistory.org

ebook History of Watertown, Wisconsin

The Monarch Co

Dornfeld-Kunert Co

Dornfeld Iron Works

812

S First

Location of

a pair of industries,

the Dornfeld-Kunert Co. and the Monarch Tractor Co.

Watertown Street Dept Bldg

810 S Second

1887

08 12 LARGE NEW BOILER FOR THE GLOBE MILL

A large new boiler,

which was drawn through our streets last Friday and placed in the Globe Milling Co.'s mill on the west side, was

manufactured at the foundry and machine shops of Ernest Kunert. It is a fine piece of work and reflects much

credit on its manufacturer. Its

dimensions are six feet in diameter, 16 feet long, with 50 flues and a steam

dome 36x48 inches.

It is as large a boiler

as has ever been manufactured in the state and cost $1.450.

With more capital at Mr. Kunert's back, there is no reason why he could not be made

one of the best boiler manufacturing establishments in the state, and some

effort to this effect should be made.

1890

AWARDED TWO BRIDGE CONTRACTS

The Board of Street

Commissioners at its last meeting awarded the contract for putting in a new

iron bridge in place of the old Boughton bridge to the Milwaukee Bridge and

Iron works for $4,577, and the contract for remodeling and widening Main Street

bridge to the E. Kunert Manufacturing Co. of this

city for $4,500 with an additional cost of $1.00 per foot for hand

railing. We are pleased to see that a

Watertown institution has secured one of these contracts, and hope the day is

not far-distant when all work of this kind wanted in this city and vicinity

will be manufactured here. WG

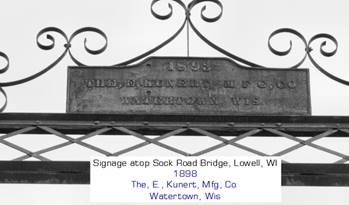

1893 DORNFELD-KUNERT

BUILT SOCK ROAD BRIDGE NEAR LOWELL

Bridge

design same as N. Second St bridge of

about the same time. Dornfeld-Kunert

also constructed the Oconomowoc Ave bridge.

This Pratt truss is one

of two bridges in Dodge County which was built by the E. Kunert Manufacturing

Company. Erected in 1893, it may be one

of the earliest truss spans manufactured by this firm. The bridge is significant because it was

built by a smaller Wisconsin bridge builder.

The structural details of the bridge offer evidence of the manufacturing

capacity of the company's physical plant.

The structure is not

significant to its location. There does

appear to have been a bridge at this spot as early as 1860, but the village of

Lowell never had a railroad connection, nor was Sock Road ever a major wagon or

automobile road. Beginning in the late

1870's, the proceedings of the Dodge County Board of Supervisors show an

increasing concern with bridge construction and replacement, The Sock Road

Bridge was one of two or more bridges agreed to for the Town of Lowell by the

Board in 1893. The Board authorized

reimbursement of half the costs for these bridges. By 1910 Sock Road was part of Rural Fire

Route No. 2.

Click

to enlarge

In 1903 the firm

changed its name to the Dornfeld-Kunert Company upon the addition of J. F.

Dornfeld of Chicago to the board of directors.

Consequently, a few years later, in 1912 the company was authorized to

transact business in the State of Illinois.

In spite of this expansion, the company's stated capital stock never

rose above $75,000.

Until bankruptcy in

1915, the firm was always described in the annual reports as a foundry, machine

shop, and structural iron works. In 1906

structural steel was added. However, as

early as 1893, the company began to advertise itself as a manufacturer of metal

truss bridges, and continued to do so until 1910. Throughout its history, E. Kunert

Manufacturing Company was a comparatively small firm, struggling to compete

with the larger Milwaukee-based and central states bridge companies . . .

To cut its expenses,

the E. Kunert Manufacturing Company appeared to be making some structural

components for its bridges with tools not specifically designed for bridge

fabrication. The larger firms could

either manufacture such parts in great quantities or order them from a foundry

or mill. Because of the large volume of

business they did, the more prominent companies could also afford to operate large punching and slotting

machinery, E. Kunert, in fact, was obtaining components such as channels and

eye bars from other manufacturers, but it may not have been able to afford the

more costly specialized machinery. Thus,

where the firm could fabricate parts with its own tools, it readily did so.

The

tools the company had on hand were, most likely, those suited for the

fabrication of boilers, and for steam and gas fitting. Interestingly, the fact that E. Kunert

ventured into truss bridge fabrication underscores the diversity of many of the

firms manufacturing metal truss bridges in nineteenth century America. Like the E. Kunert Manufacturing

Company, they did not limit their plant operations to the design and

fabrication of truss spans.

1893 Otto Biefeld, Sr. (1861-1906) secured employment with the Kunert Bros. Machine Co.

and was employed by that firm till 1893, when he and his brother Richard formed

a partnership (Otto Biefeld Company).

10 13 Water tower (stand pipe) and waterworks boiler

contract proposed for Kunert Manufacturing.

-- -- SOCIETY HOLDING: 1895 E.

KUNERT SIGNAGE

Similar seen

previously atop Kunert-constructed bridges (approx.

60 lbs)

1899

10 03 CONTRACT FOR LOCK IN THE OCONOMOWOC RIVER

The extensive work contemplated by the

Oconomowoc Waterways Company in connecting some of the lakes of that region so as

to provide continuous navigation will have a start this fall. The contract for a lock in the Oconomowoc

river, near Armour bridge, has been let to a Milwaukee marine mason, while the

E. Kunert Manufacturing company of this city, will put in the iron work. The great gates will open and close on ball

bearings. To keep the bed of the river

dry and to enable the work to proceed, a coffer dam, 70 by 18 feet, will be

built and a mammoth pump kept busy expelling the water. December 11 is the time limit for the

completion of the mason work. WR

1900

-- -- MANAGEMENT NOTE

E. Kunert Mfg. Co., Ernst Kunert,

pres., August Tank, v-pres., Charles Kunert, sec., Fred. Hoffman, treas. Machine shop and foundry, foot First Street.

02 13 MONROE COUNTY CONTRACT

The E.

Kunert Manufacturing Company recently completed the building of four iron

bridges in Monroe County. Altogether the

company has put in twelve bridges in that county and one in Rock County, which

fact, we should think, speaks volumes for the concern’s ability to satisfy its

patrons. Ernst Kunert president of the

company, returned last week from Monroe County, where he had been

superintending the work. WR

09 21 Williston,

ND CONTRACT

The E.

Kunert Manufacturing Co., of this city, has the contract for putting in the

steam heating apparatus in an opera house and hotel at Williston, North Dakota,

John Bruegger, a recent visitor in our city from that town having given the

order for the same. WG

12 07 FILL OUT PORTION OF MILL RACE

Last

week an argument was entered into between the Chicago, Milwaukee & St. Paul

Railway company on the one side, and R. P. Koenig &Co. and the E. Kunert

Manufacturing company on the other side, whereby the privilege is extended to

the former and the latter parties to fill out that portion of the east side

mill race extending from Milwaukee Street bridge north to the old Bennett

machine shops plant. This privilege, we

are informed by the railway company’s attorney, Harlow Pease, will not cost the

company one cent, the local institutions controlling the water rights in the

race agreeing to the conditions specified without any consideration, except

that the railway company shall furnish the material for filling up and perform

the work. WG

12 14 FILL OUT PORTION OF MILL RACE

The Watertown Republican appears to be

greatly grieved because the mayor and common council of this city acted wisely

in settling the "mill race matter," and, as it says, "this is an

old affair and there is not much-needed discussing it further," as it has

been fully discussed in the city papers – still it might be well for us to

inform the Republican that the Gazette editor has taken a private poll

of our citizens on the question and knows whereof he speaks. "The exact figures," as called for

by the Republican of the poll taken

by us, are: Two opposed to the

settlement of the mill race matter, and the rest of our citizens in favor of

it. WG

1901

02 06 KUNERT MANUFACTURING TO

BUILD NEW BRIDGE

The material for the new Cady bridge

is being received by the E. Kunert Manufacturing company and work will begin

shortly. The contract calls for the

completion of the structure by April 20.

WR

05 01 CONSTRUCTION OF NEW CADY

STREET BRIDGE

On Friday the A. Kunert

Manufacturing Company began the construction of the new Cady Street

bridge. The structure will consists of

six spans, each fifty-seven feet long and weighing six tons apiece. It is expected to have the bridge completed

by June 1. WR

06 14 NEW CADY STREET BRIDGE

Last Monday the Board of Public

Works inspected and accepted the new Cady Street

bridge just erected by the Kunert Manufacturing Co., and on Tuesday

afternoon it was opened to traffic. The

bridge is a first-class one, and reflects much credit on our home

institution. It is built entirely of

iron, excepting the paved roadway and sidewalks. The work was under the personal supervision

of our fellow-citizen, A. F. Baumann, one of the best-posted bridgemen in the

state and a member of the Kunert Co. He

scrupulously looked after every detail.

The result is a first-class job.

It is a three-span steel bridge, 18 feet wide, and cost $6000. WG

09 13 FORT ATKINSON WATER TOWER

On Wednesday A. F. Baumann of the

E. Kunert Mfg. Co. went to Fort Atkinson with force of men to put up the water

tank and pump for the waterworks system there.

The tank and pump attachments were manufactured at the Kunert works

here. The tank is to be 34 feet high and

22 feet in diameter, and will be mounted on a brick tower 74 feet high. WG

1903

DORNFELD-KUNERT COMPANY

FORMED

Firm changed its name

to the Dornfeld-Kunert Company upon the addition of J. F. Dornfeld of Chicago

to the board of directors.

1906

01 31 Few

in this city are aware of the extent of the business done by The

Dornfeld-Kunert Company. Its works cover

a large area of ground and a large force of men are employed in both the

foundry and machine shop in turning out the large orders received from distant

points. The company is shipping 300 tons

of structural steel to Lockport, Ill., for the Illinois

River Drainage canal, and they still have other orders to be filled to say

nothing of other orders booked for future delivery. It is one of the permanent manufacturing

industries in the city and is a local enterprise, having grown to its present

size from a small beginning in the years past. WL

1906

04 19 The Dornfeld-Kunert company desires

a small spot of ground near its shops upon which to erect an office building

which will be constructed of structural steel and brick and be absolutely fire

proof. The city should sell it to the

company for a nominal price. Why? Because it is an industry owned entirely by

Watertown people, employs about 85 hands and its pay roll amounts to about

$1,000 per week, which is spent in this city to add to its prosperity and

growth. Our business men are contributing

thousands of dollars to induce industrial enterprises to locate here, and it

seems strange that the city should withhold from a home concern the small favor

asked for. As far as endangering city

property its concern, there is nothing in the claim, for the building

contemplated will be some distance from the water works plant and will be

fireproof. It is a matter in which all are interested and each citizen should

give expression especially to the aldermen of his ward . . . WL

11 09 St. P. Ry. ESTABLISHES WORKS HERE

The C.M&St.P. Ry.

Co. is building a carpenter shop on the site of the old rolling mill near the

junction, which in time may develop to large proportions. The company has also established temporary

bridge repair works south of the depot,

and the Dornfeld-Kunert Co. has contracted to repair bridges that the company brings into the city for

repairs. One bridge was recently brought

here on eight flat cars. The paint is

taken from the iron work by means of a sand blast, and when removed the iron

looks like polished steel. It is quite

interesting to watch the work being done.

WG

1907 CONSTRUCTED

OCONOMOWOC AVENUE BRIDGE

11 27 The

new iron and steel bridge being constructed across

the Rock River at Oconomowoc Avenue is almost completed and will be ready

for traffic by the first of December. It

is a structure that reflects credit upon the builders, the Dornfeld-Kunert

Company of this city, whose bid was $12,500.

The cement work is all finished and the work of laying the brick paving

is well under way. The length of the

bridge is 256 feet, four spans of 64 feet each. The width of the roadway is 17

feet, of concrete with brick paving, while the sidewalk is five feet six inches

of cement. A. F. Baumann of the

Dornfeld-Kunert company has had supervision of the construction work and not a

detail has been overlooked. WDT

1908

07 22 BRIDGE

OVER RR TRACKS FOR WATERTOWN INTERURBAN

The overhead bridge which will carry the

electric cars (Watertown interurban) over the

Milwaukee road track in what is known as Richard's cut will be rolled into

place tomorrow morning. Everything is

now in readiness and it certainly will be an interesting sight. The steel structure known as a pony truss,

was built for the electric company by the Dornfeld-Kunert

company of this city. It was erected on

the north side of the railroad tracks and will be rolled into place on

rollers. There is a gap over the tracks

42 feet wide which must be left open for the passage of trains and the truss

will be carried out over that without any support except its own weight on the

land until it touches the falsework on the other side and eventually be placed

in the concrete abutments. It is

possible that a locomotive on the electric line now stationed south of the cut

will furnish the power.

The truss is of steel, 96 feet in length, and

will rest upon huge concrete foundations built last spring by Edward Racek of this city.

The truss will be at a height of 24 feet above the railroad tracks,

sufficient to clear any train. The rails

have been laid up to the south side of the cut, but are not yet laid between

the cut and Western Avenue, but this will require only a short while. Watertown Daily Times,

July 22, 1908

1909

06 04 Amoskeag fire engine owned by city of Columbus,

Dornfeld-Kunert secured contract for new boiler on WG

06 18 Line

shaft of Dornfeld-Kunert shop attached by belt to

a “Nash Gas Engine WG

09 03 Overhauling Waterloo’s Silsby

steamer

WG

IRON WORKER CREW. The Dornfeld-Kunert Co., once was among

Watertown's most important and widely known business concerns. It built many iron bridges and operated a

boiler works, a foundry, machine shop, etc.

It employed a large force of skilled workers, many of them experts in

their field. Picture owned by Clarence

Peterson; he worked for the concern and is shown seventh from the left in the

front row. WDTimes, 03 18 1967

1910

04 29 THE "LONG GEORGE" WILL MAKE THE

"FIRE FLY"

Several days ago the

Dornfeldt-Kunert Co.'s employees backed another fire engine from Fort Atkinson

into their shop for a new boiler and other repairs, similar to the work done

for Columbus on their "prize winner."

The Fort Atkinson engine was built by Cole Bros, fully forty years

ago. Pawtucket, Rhode Island, mechanics

produced this steamer that bears, on a brass plate, the following . . . WG

1911

01 26 GAS PRODUCERS

The gas producers

manufactured by the Dornfeld-Kunert Co. of this city are meeting with general

favor wherever introduced, and present indications are that this Watertown

industry will grow to great importance here.

There are hundreds of

bakers, candy manufacturers, grocers, etc. in this country using city gas for

fuel and paying anywhere from 60 cents to $1.50 per 1000 cubic feet for the

same. Such was the case at the Bowen

Grocery, Allentown, Pa., until recently, when they installed their own gas

making plant, which is used for supplying for the following purposes:

To run a 30 H.P. gas

engine, which is used for furnishing light and power, to supply bakers' ovens,

a coffee roaster, which is used also for roasting peanuts, a kitchen range, candy

stoves and other appliances. This

gas-making plant was installed by the Dornfeld Co. of Watertown, Wis., and the

following letter lately received from Mr. James Bowen of the Bowen Grocery Co.

shows the saving effected:

Gentlemen:

"We have just completed

the installation of one of your sixty H. P. Economic Gas Producers. As our plant is a very complicated one, after

persistent efforts, we are accomplishing all that the plant was intended for. With our sixty H. P. Producer we are

furnishing enough gas to run our thirty H. P. engine, which supplies all the

electric light current we need in the building, besides furnishing power for

our elevator, coffee mills and refrigerating plant; also furnishing gas for our

confectionery stoves, coffee urns, our kitchen range and bake ovens.

Our power heretofore

has cost us not less than Three Thousand ($3000.00) dollars a year, with gas at

ninety cents per thousand and electric current at .026 per K. W. This same amount of power with the gas

producer will cost us no more than from eight hundred ($800.00) to one thousand

($1000.00) dollars a year, with coal at four dollars ($4.00) per ton.

We feel confident that

the gas producer will be the coming medium for furnishing economic power and

heat."

Yours very truly,

John Bowen.

The gas producer plant

consists of a gas generator and a gas cooling and cleaning tower, together with

a gas booster, the whole occupying a space of 9x17 feet. The plant is filled with coal every three

hours and the ashes removed once in twenty-four hours. The plant is in continuous operation day and

night and there it always sufficient gas to meet the requirements. WG

1912

03 28 PROFILE OF THE COMPANY

The name of the Dornfeld-Kunert Co., one of our most important, prosperous

and valuable industries. They have grown

with the growth of the city, maintaining such a dignity in the manufacturing

world as reflects credit to her as a manufacturing city.

The company was

established by E. Kunert in 1888 and incorporated

under the name of E. Kunert Manufacturing

Company. In 1904 it was reorganized and

changed to the Dornfeld-Kunert Co., with the

following officers: D. H. Kusel, president; J. F. Dornfeld, vice president: F. A. Hoffmann, treasurer: Chas. Kunert, secretary and A. F. Baumann, manager. The company

was first incorporated for $25,000, afterwards for $50,000 and now $75,000.

The company's plant

covers about two acres of ground upon which is erected a group of substantial

buildings, which are fully equipped with special machinery representing the

utmost perfection of mechanical ingenuity, operated by gas, which is

manufactured by their gas producer and furnishing employment to from 75 to 100

people, mostly skilled workmen.

A short time ago the

plant was completely overhauled and a new electric crane put in. They make a specialty of steel construction

and boiler works of all descriptions, such as bridges, fire escapes, structural

work, ornamental store fronts, tanks, gray iron castings, and the Dornfeld malting machinery, also economic gas producers.

The products of this

establishment are used all over the United States. The present officers of the company are J. F.

Dornfeld, president; J. F. Prentiss, vice-president;

F. Hoffmann, treasurer: F. Schmutzler, manager and

secretary, and A. F. Baumann, sales manager.

The general manager, Mr. F. Schmutzler, is no

stranger to our people having been born and raised in our city and was formerly

in the lumber business and was a member of the well-known lumber firm of J.

Weber & Son for twenty years and has been general manager of the Dornfeld-Kunert Co. since 1908.

The management is in

the hands of gentlemen of progressive ideas, who understand their business in

every branch and detail and to them is largely due the gigantic proportions and

productive vigor of the Dornfeld-Kunert Company's

manufacturing establishment.

05 16 Contract

for addition to the Lutheran Home for Feeble-Minded

07 18 Firm Gets Contract.

A. F. Baumann, representing the Dornfeld-Kunert Mfg. Co. of Watertown,

was in the city [Ft. Atkinson] and closed a deal whereby his firm will build

beneath the Perry building on Rock River twenty-four concrete abutments of pillars

to replace the wooden piles. The latter

have become rather unsafe, especially when the high water stage is reached, as

was the case this spring. The work of

putting in the cement supports will be commenced in the near future, as the

present low water simplifies the task. –

Ft. Atkinson

Democrat.

Dec Mr. Cyril J.

Atkinson, the

inventor of the Atkinson gas producer, has severed his connection with the

Dornfeld-Kunert Company of Watertown, Wis.

Mr. Atkinson's services and the use of all his patents have been secured

by Fairbanks. Morse & Company, of Chicago, and a number of Mr. Atkinson's

inventions will be incorporated at once in the FairbanksMorse gas

producers. Metallurgical and Chemical Engineering, December 1912, p 824.

c.1912

1913 DEATH OF

FRANK KUNERT

11 13 Frank

Kunert, aged 63 years, died at Live Oak, Florida, November 1, 1913, where his

remains were interred. His wife, one

daughter and one son survive him.

Deceased formerly resided here and was a member of the firm of Kunert

Bros., who conducted for many years what is now the Dornfeld-Kunert Co. of this

city. He was a brother of Ernst and Edward Kunert and Mrs.

John Kuester of this city. WG

1914

EMPLOYEES DEPART FOR OTTO BIEFELD CO.

In 1914 Arthur Kuenzi,

formerly chief engineer of the Dornfeld-Kunert Company, joined the Biefeld Co.

After that was completed other key men from Dornfeld-Kunert Company,

such as A. F. Schumacher, accountant, William Kleineschay, engineer and Herman

Gerth, manager of production, joined the firm.

10 08 WILL

CONTINUE OPERATIONS

Trustee

in Bankruptcy A. F. Baumann, who was given charge of the affairs of the

Dornfeld-Kunert Company of this city, states that the plant would be in

operation for several weeks to complete contracts already begun, following

which the plant will probably be closed pending the orders of Judge Sanborn in

the matter of selling the personal property, the real estate or both.

The

company was adjudicated bankrupt September 12th on the petition of Chicago

creditors, represented by Quarles, Spence and Quarles of Milwaukee. Mr. Baumann was elected trustee at the first

meeting of the creditors on September 29.

The trustee is now taking stock, but the inventory cannot be completed

until the plant closes. Kading &

Kading are the attorneys for the trustee.

Mr. Baumann states that he could give out no figures as yet on the

financial standing of the firm. WG

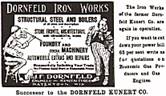

Dornfeld to Continue Business

Dornfeld

Iron Works

All Work Given This New Firm Will

be Handled

Promptly By Skilled Workmen

Click to enlarge

1915

05 27 Some weeks

ago the Structural Steel and Iron Works, Foundry and Machine Shop of the

Dornfeld-Kunert Co. of this city were purchased by J. F. Dornfeld, who will

conduct the business in a manner as before, doing all kinds of structural iron

work for buildings and allied trades. In

this connection we will furnish all kinds and sizes of boilers and do boiler

repairing of any and all kinds.

We shall be prepared to furnish

repairs for boiler fronts, fire boxes and the like and in most cases will no

doubt have pattern for same. With the

aid of a light auto truck we can get to most such work quite promptly. Light or heavy smoke stacks will be made and

tools for erection can be furnished.

Special attention will be given

to the foundry; and all castings that may be wanted will be made first class

and at reasonable prices. We have

patterns on hand in the foundry for almost anything required. All these patterns are properly numbered,

booked and shelved so that customers can readily get a duplicate casting by

referring to a number on the casting.

Patterns belonging to customers and left here will be treated in the

same way. It will be a principal object

to provide first class tools in addition to those on hand in the machine shop

and have good mechanics who will understand and can do any work that we may be

favored with.

We will have shafting, pulleys, hangers,

etc., in stock and will furnish anything in that line at market prices.

Any repairing of automobiles or

auto trucks will be done by expert mechanics.

We will employ great accuracy and

promptness in line of machinery work, whether it is new or repair work.

We will endeavor to keep in

stock, as much as possible, repairs, castings, etc., for any machinery that may

be called for. It is our intention to be fair in all deals in that we want your

trade and cooperation. Watertown Gazette

06 24 The plant of

the defunct Dornfeld-Kunert Company Watertown, Wis. is now being operated in

all departments by John F Dornfeld who purchased the property at auction He is

specializing in fabrication and erection boilers stacks and operating the

foundry on custom work. The

Iron Age, June 24 1915, p 1433.

08 26 Dornfeld Making

Engine—J. F. Dornfeld, president of the defunct Dornfeld-Kunert Iron Works,

Watertown, Wis., has purchased the assets and organized as the Dornfeld Iron

Works. The company will make a specialty

of extras and repairs on automobiles and has established a well-equipped

department for this purpose. A foundry

and machine shop is being conducted and the concern is manufacturing gas

engines and gas producers. The

Automobile, August 26 1915, p 403.

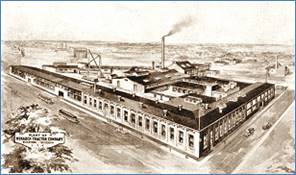

The Monarch Tractor Company was

incorporated

The first work undertaken by the

new Company in its plant was the building of the early models of the well-known

Luce Sugar Cane Harvester, which in its latest development is now performing

remarkable work in the Cuban cane fields.

Prior to the organization of the

Monarch Tractor Company, its incorporators had been working for several years

on the development of a crawler type of tractor modeled somewhat after the

military tanks. This work was continued

in the new company and resulted finally in the completion of the Monarch

Tractor as a commercial product.

These tractors are now working

successfully in every state in the Union and in many foreign countries. During the war the Company employed about 200

men and turned out six completed tractors per day. Large numbers of these tractors were shipped

to France and there took part in operations in connection with the Great War.

The company has always aimed to

support local institutions, and to develop a business which would be of benefit

to the community in which it is so fortunately located, and to make the city of

Watertown well and favorably known wherever Monarch Tractors may go. Watertown High School Orbit, 1921

The first work undertaken by the

new Company in its plant was the building of the early models of the well-known

Luce Cane Harvester sugar cane harvester.

[source]

1918

-- -- SUGAR CANE HARVESTERS

BUILT BY MONACH TRACTOR AND BY OTTO

BIEFELD CO.

CROSS

REFERENCE NOTE

OF 1921: The Luce Sugar Cane Harvester

Co., which has been located in Watertown, Wis., has established offices in New

York and later will acquire a plant either in that state or in New Jersey. A number of machines have been built for the

company at the plant of the Monarch Tractor Co. in Watertown and additional

machines by the Otto

Biefeld Co. of that city. It is reported that the machines have been

thoroughly tested in the cane fields of Cuba and the results have been

sufficient to encourage the company in extensive production. Farm Implement News, Volume 42, 1921

1919 1919,

Advertisement

1920

08 12 Improvements at Monarch Tractor Co.

plant WG

1920,

Fold-out pamphlet, similar to the Caterpillar Tractor

1941 JOHN F. DORNFELD, 1855-1941

Word has been received here of

the death of John F. Dornfeld, former Watertown resident, at his home in San

Diego, Calif. He died three weeks ago.

Mr. Dornfeld was president of

the old Dornfeld-Kunert Company here, which occupied the building here known as the Monarch Tractor plant.

He was 85 years of age and

apparently was in good health, a message from his daughter, Leona Dornfeld,

states. He passed away March 20 while

riding in a car. He was rushed to a fire

station near-by, where a pulmotor was used in an effort to save his life. Death

was due to a heart attack.

Mr. Dornfeld was born near

Watertown on August 3, 1855. He attended

Northwestern College here, and after he

finished his schooling started his career as an architect and mechanical

engineer. Early in his career he built

homes and churches in the vicinity, St. Mark’s church

being one of his early efforts. For

several years he built flour mills, after which he entered the malt house

building field in which he spent 50 years.

He had about 50 patents in the

malt house construction field. Among the

larger plants he installed were the Rahr Malting Company of Manitowoc, the John

Kam Malting Company of Buffalo, N. Y., and the Columbia Malting Company of

Chicago.

Shortly after the prohibition

era began in the late 1900’s, the Dornfeld-Kunert plant here was closed and Mr.

Dornfeld left Watertown and took up his residence in California. After the prohibition era, he became

associated with the Otto Biefeld Company. Since that association, which began in

October, 1933, he built a number of plants, one for the Fleischman Malting

Company at Chicago, one for the Hamm Brewing company at St. Paul, Minn., and

another for the National Malting Company at Paterson, N. J., and many other

smaller installations. Since his

association with the Biefeld Company, he spent part of his time in

Watertown. He spent two months here last

summer. His work in the malting field

will now be carried on by the Otto Biefeld Company here.

Surviving are his wife and

daughter, who live in San Diego.

Mr. Dornfeld was well known

here and highly respected. His death

will be learned with regret.

> CROSS REFERENCE NOTE, 1890: John E. Dornfeld

was the architect and contractor for new spire at St.

Paul's Episcopal church.

1967

11 21 BUILDING TO BE ACQUIRED

The former Monarch tractor building,

located between South First and South Second Streets, can be acquired for

$90,000, the members of the City Council, meeting as a committee of the whole

last night, were informed. At tonight’s

regular council meeting a resolution to acquire the property will be

introduced. It is anticipated that the vote will be favorable. If acquired, the building will be utilized by

the street department, which has its quarters directly to the west. The property, owned by Atwater-General

Corporation, is assessed at $153,100, and in addition, two lots, included in

the deal, are assessed at $1,175.

c.1975

2006

11

30 PROPOSED

PUBLIC WORKS FACILITY

Members of the Watertown

Public Works Commission got a firsthand look at the conceptual plans for the

proposed public works facility that would be located at the current street

department parcel on South Second Street during a special meeting Wednesday

night. After viewing the plans the Public Works Commission made a

recommendation to the Common Council to allow Matthew Long of Angus-Young

Associates Inc. to start drafting a site survey for the property that would

confirm the locations of easements, utilities, wells, pits, grades and other

site issues.

The conceptual plans

presented by Long include the anticipated city acquisition of a 1.5-acre parcel

next to the street department site that is owned by We Energies. The plans also

call for the street department to take over the water department offices on

South First Street. The water department would then move next to the treatment

plant location on the city's south side.

2007

04

12 PURCHASE

LAND FOR NEW PUBLIC WORKS BUILDING

A resolution

authorizing city officials to purchase land for the proposed public works

facility will be on the agenda of the Watertown Common Council when it meets

Tuesday at 7 p.m. The city is looking to

buy the properties at 101 Western Ave. and 805 S. First St. so the proposed

building can be expanded at the current street department facility site at 810

S. Second St. The properties are owned

by Thomas Torp, president of T & T Masonry Inc. in Oconomowoc. The resolution allows city officials to

purchase the two properties for $206,000.

The agreement also calls for the city to give Torp the vacant lot at 905

S. Second St. that is used as a parking lot for the street department

employees. That land is valued at

$30,000.

06

19 CONTRACT FOR

NEW PUBLIC WORKS BUILDING

The Watertown Common

Council Tuesday unanimously approved a resolution authorizing city officials to

sign a contract for the architectural and engineering services related to the

construction of the new public works building on South Second Street. The contract for the new facility is with

Angus-Young Associates Inc. from Janesville for $340,650. The city could also be responsible for up to

an additional $55,500 in reimbursement costs.

09

12 UPDATE ON

PUBLIC WORKS FACILITY

The Watertown Common

Council Tuesday evening received an update on the proposed public works

facility that would be built on South Second Street. The Watertown Public Works Commission

recently voted to spend a maximum of $7.25 million. That proposal was approved by a vote of four

to two. The commission also looked at

several other figures but ultimately decided on $7.25 million. The $7.25 million figure was brought in front

of the council so public works commission members could see if they were headed

in the right direction, but many aldermen said they were not prepared to make a

final decision on the costs at this time.

09

25 PUBLIC WORKS

FACILITY SCALED DOWN

An ordinance creating

a planned unit development zoning designation for the construction of a

proposed new street department facility was given the green light under its

first reading Tuesday by the Watertown Common Council. The unanimous vote to move forward with the

ordinance comes after the approximately $6.5 million facility on South Second

Street was scaled down in price from an estimated $7.25 million. The reduction in price was achieved by

cutting back on square footage, eliminating a jib crane and a wash bay catwalk,

and by agreeing to have the street department handle the demolition of the

existing building. In addition, the city

can expect to save $167,000 by completing the project in a single phase vs. in

multiple phases.

2008

02

26 NEW STREET

DEPT FACILITY DISCUSSED

Several topics

dealing with the new street department building were discussed Tuesday at the

Watertown Public Works Commission meeting.

According to city Engineer Joe Radocay,

commission members reviewed the final plans for the new facility and talked

about the upcoming bidding process.

"Those bids will be received on March 25," Radocay

said. "We will analyze the bids

received and then bring it back to public works." Commission members also received news from

city attorney Tom Levi that the owners of Luna's Market have decided to move to

a building at the 200 block of South Third Street and have signed a lease. S treet Department Superintendent Rick Schultz said the Lunas

will be moving their operation from Western Avenue to South Third Street in

early March. The Public Works Commission

was told the acquisition of the We Energies property south of the current

street department site is looking positive, Schultz said.

03

02 NEW STREET

DEPT FACILITY PLANNED

The Watertown Street Department

is in the process of temporarily moving its operation to the former Applied

Molded Products building on South Montgomery Street to make way for its brand

new facility on South Second Street.

Street department Superintendent Rick Schultz said today the move is

going smoothly and he hopes to have all of the department’s equipment and

materials at the Applied Molded Products building by the end of March. “All of the equipment and materials are

heading over there and we have about a third of our department moved,” Schultz

said. “We hope to be close to about a

half in the next week and a half. If the weather holds, I would like to have

everything over there and operating on March 31.”

03

24 CONTRACTOR

FOR NEW STREET DEPT FACILITY

Members of the Watertown

Public Works Commission didn’t exactly select the contractor that will build

the new street department facility, but they did narrow the field down to two

candidates. The Public Works Commission

Tuesday night made a recommendation to the common council that whichever

company produces the lowest bid should be awarded the contract for the new

building on South Second Street. Miron

Construction Co. Inc. in Neenah submitted a base bid of $4,626,565 and Maas

Bros. Construction in Watertown supplied a base bid of $4,635,000. Public Works Commission members didn’t make a

decision between the two construction companies Tuesday night because

representatives from Angus-Young Associates Inc. first need to verify the language

in the bids to see if the numbers are accurate.

Angus-Young, which is located in Janesville, is an architectural and

engineering firm that has been working with the city on the public works

building project for the past 3 1/2 years.

05

07 DEMOLITION

OF FORMER STREET DEPT BLDG

Demolition of the

former Watertown Street Department building on South Second Street began

Thursday as part of an effort to make way for the construction of the city’s

new public works building at the site. Presently relocated to the former

Applied Molding Products building, the street department plans to move into the

new facility early next year. The building being razed was formerly the

location of a pair of local industries, the Dornfeld-Kunert

Co. and the Monarch Tractor Co.

05

08 LOCATION OF

A PAIR OF FORMER INDUSTRIES,

THE DORNFELD-KUNERT

AND THE MONARCH TRACTOR

Demolition of the

former Watertown Street Department building on South Second Street began on May

8, 2007, as part of an effort to make way for the construction of the city's

new public works building at the site.

Presently relocated to the former Applied Molding Products building, the

street department plans to move into the new facility early next year. The building being razed was formerly the

location of a pair of local industries, the Dornfeld-Kunert Co. and the Monarch

Tractor Co.

Click upon to enlarge

Demolition of former

Dornfeld-Kunert, Monarch Tractor and Street Dept bldg

Construction Street Department Building

2009

Dedication of new Public Works

Facility; tours of

facility. Children had the opportunity

to get up close to city trucks and construction equipment.

Brochure

printed in conjunction with dedication of facility

![]()

History of Watertown,

Wisconsin