website watertownhistory.org

ebook History of Watertown,

Wisconsin

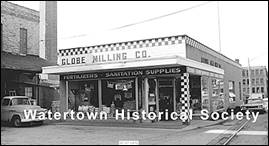

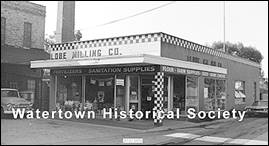

Globe Mill

317-321 S.

Water

In its day, the old mill on South Water Street was the hub of activity for a farming community.

Hundreds of gears turned as grain was pulverized into flour, generated by power from the Rock River.

GLOBE MILL

1853: One of three mills in town:

1] West side of river,

Built 1848 Red Mill, Big Brick Mill, Blanchard Mill

Empire Mill, former Emerald Mill

Globe Mill

A to Z Farm Center

c1992 Bought by Empire Globe

Corp.

2001 Building destroyed by

fire

2] East side of river, Yellow Mill, built 1842. In 1848 upgraded from water power to steam power

3] East side of river, Big Brick Mill, built 1848.

In 1881, in company with Jonas Sleeper, Fred Miller engaged in the manufacture of flour at the Brick mill, the site of the present waterworks plant. The firm was known as F. Miller & Co., which later became the Globe Milling Co., the output of which at one time was 70,000 barrels of flour a year, and sold out his interest in 1885.

The Empire Mill, first known as the Emerald Mill, was built by Fay & Cramer of Milwaukee on the west side of the Rock River in 1848. On the opposite side of the river, built in 1842, was a mill known as the “Old Yellow Mill” and then, in 1848, another called the “Big Brick Mill”. In 1853 there were three flouring mills as they were then called. This was boom time in Watertown.

____________________________________________________________________________________

1842 OLD YELLOW MILL BUILT

The first of the mills was built in 1842 by Luther A. Cole and Edmund S. Bailey and was known as "The Old Yellow Mill." This was only six years after Timothy Johnson, the first settler appeared upon the scene. Its location was that now occupied by the Electric Power Co. plant at the western end of what was then known as "The Rough and Ready Dam." Ownership changed several times in the first few years. In 1848 the owners of Old-Yellow built another mill on the present site of the City Water Power Plant. This was enlarged in the eighties and was generally known as "The Big Brick Mill." Its capacity, actual, not rated, was 800 bbls. daily and by consolidation it became the main plant of the Globe Milling Co. group. The same year, 1848, there was built "The Emerald Mill" on the site now occupied by the present Globe Milling Company plant. This mill burned in 1871 but was immediately rebuilt.

In 1874,

Mr. Christian May, a successful logging and lumber operator, purchased the

Emerald Mill and shortly after brought about a consolidation with the Big Brick

Mill, operating as the Globe Milling Company, giving the Globe group, as

improvements and expansion took place, a combined capacity of approximately

1,000 bbls. daily.

From that time on The

Emerald Mill was known as The Empire Mill. It was at this time that Mr. Christian May's

eldest son Gustavus took over the management of The Big Brick Mill, while son

Edward managed The Empire Mill.

It is necessary to retrace our steps to 1891 to note the destruction of the Big Brick Mill in that year by fire. It was not rebuilt and the Empire Mill assumed the name of the operating company, and has been known since that date to the present as the Globe Mill.

In 1898 ownership and management of the mill was taken over by Henry Mulberger and Wm. D. Sproesser. In 1904, as a partial offset to capacity lost by the destruction of The Big Brick Mill, Messrs. Mulberger and Sproesser purchased a 250 bbl. mill at Oconto, Wis. This was moved to Watertown and from then on the Mill operated two 250 bbl. units under one roof, one unit grinding wheat, the other, rye.

During the next few years the new owners found it necessary to devote more of their time to their banking and other business interests, and George Manschot, with many years of experience with the well-known milling firm of J. B. A. Kern & Sons, Milwaukee, was engaged to take over active management.

In 1917 still another change in ownership took place. Shane Bros. & Wilson Co., owners and operators of the Milbourne Mills in Philadelphia had entered upon a program of expansion which included not only the erection of new mills, but the purchase of established mills throughout the mid-west.

Included in those purchases were the Globe Milling Co. and a 500 bbl. mill in two 250 bbl. units at Portage, Wis., owned but not recently operated by York Bros. of that city. Extensive improvements were undertaken particularly at the Portage Mill which was practically rebuilt with the addition of a large and well equipped warehouse.

In the meantime the Watertown mill had been turned over to rye exclusively, and by 1919 the rebuilt Portage mill was ready for operation.

At that time the present management came to Watertown with instructions to combine the Watertown and Portage mills financially as well as in general management and sales. It was an unwise decision. The Portage mill was heavily in debt due to improvements and new buildings. It had neither established trade nor brands. The United States public had been forced to use a percentage of substitutes for wheat flour during the war and with the removal of those restrictions wanted nothing to do with substitutes, with which they unfortunately classed rye. It was impossible under those conditions to sell successfully the combined rye capacity of the two mills, totaling 750 bbls. daily.

The Portage mill continued to be a drag on the well established Watertown mill, and it was sold in 1924 to a Chicago contractor thinking to make a miller of his son. It burned to the ground before it had really gotten into operation under the new owners.

The over expansion of the milling industry during the war, with the resulting scramble for business at unprofitable prices combined with the general commodity price collapse in the early twenties was disastrous for Shane Bros. & Wilson Co. in their over-expanded position. They were obliged to relinquish their interests in the two Globe Mills and reorganization of the Globe Milling Co. became imperative. It was at this time that New York and Milwaukee capital made substantial investments and together with the interest held by mill personnel, ownership remains much the same today as then. Since World War I we have been the largest exclusive rye mill in the United States—not an entirely happy distinction under the exigencies of war.

When the Mays

sold their interests in 1898, Edward May established himself as a broker in

Pittsburgh under the name of Edw. C. May & Sons. The business is still carried on under the

same name by Edward's son Harry C. May, and through all these years has sold

Globe flour in the Pittsburgh territory.

The name May has been closely associated with the Globe Mill for the

past seventy-one years.

____________________________________________________________________________________

Changes of ownership in the early days were frequent. The roster of early owners includes such names as Luther A. Cole and Edmund S. Bailey, builders of the original "Old Yellow Mill" in 1842. Subsequent early owners of this mill and two others included in the Globe group were Ebenezer Cole, Linius R. Cady, Jacob Weber, J. H. Sleeper and Philip Quentmeyer. Still later in the mills history are the names of The May Bros., Mulberger and Sproesser.

____________________________________________________________________________________

A country mill, in early days, was something more than just another manufacturing establishment. It was separate and distinct, of the very woof and warp of the communities life and progress. Here came the farmers with their grain to sell and supplies to buy. Here they gathered in visiting groups to discuss their crops, their plans and to roar in rib-racking laughter as some story teller spun his yarn. Here, too, came the towns people for their flour, the feed for the horses, cows and chickens, kept by the thrifty householder to combat the not so high cost of living. The mill no doubt could vie with the historic New England town pump as the source of many a wild tale and rumor. The farm wife, too, brought her eggs and butter to be traded at the general store for needed groceries and calicoes. The mill yard was stacked high with cordwood traded in by the farmers as they cleared their heavily forested land, furnishing a cheap fuel for stoking the mill boilers. Dollars in those early days were scarce, but barter played an important part in keeping the wheels of commerce turning.

____________________________________________________________________________________

1848 EMERALD MILL OPENED

Rock River Pilot,

03 29 1848

The splendid new mill, on the west side of the river, belonging to Messrs. E. & J. Cramer of Milwaukee, and B. F. Fay of this village, went into operation on Thursday last. The mill building is 40 by 45 feet, and five stories high. It was drafted by that able and widely known millwright and machinist, Ira Miltimore of Chicago, and is designed for four run of stone [four run of stone is taken to mean four working pair of millstones], two of which are now working successfully, each being driven by one of Rose’s improved re-action wheels.

A wheel of the same description turns a perpendicular shaft, which passes through all the floors, propelling the machinery that works the smutter [note: a smutter or fanning mill removes the smut, mold, fungus and any dirt clinging to the grain], which is in the basement; the screen, blower, meal conveyors, and return conveyors, which are on the second floor, and the bolts, which are on the fourth or bolting floor. The third floor is occupied by the stones, etc.; the fifth as a grain store. The bolt chest is one of the finest in design and finish we have ever seen. It is 21 feet long, 14 wide, and 14 feet high, and contains five bolts. The whole of the complicated, yet simple and beautiful machinery attached to the main shaft is propelled by 98 inches of water. With 350 inches of water to propel the two wheels, each run of stone has ground wheat at the rate of 25 bushels per hour, and it is believed that 30 bushels per hour can readily be ground by each run of stone. Thus this mill without the additional two run of stone, can convert flour from 3 to 400,000 bushels of wheat annually.

The millwright work has been under the immediate supervision of Mr. Thomas Keegan, a mechanic of no ordinary skill and ability. Mr. Fox, an able and experienced miller, formerly of the Niagara mills, Black Rock, directs the flouring operations. He is assisted by his brother, who is also a master of his profession.

Much credit is due to the proprietors of the mill, for their persevering enterprise, and to the mechanics employed in its construction, for the science and skill they have displayed. No expense has been spared in its completion and everything in and about it has that highly finished appearance so desirable in mills or other buildings but so seldom found in a new country. Those who are competent to judge say that it is unquestionably the best mill in Wisconsin. It is a great acquisition to our village and the surrounding country; and we have no doubt that the proprietors will realize their most sanguine expectations in the deserved success of the Emerald Mill.

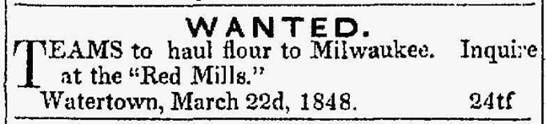

1848

Rock River Pilot, 05 03 1848

1858

07 29 LOWER DAM REBUILT AFTER FLOOD

The New Dam - Mr. W. H. Blanchard and Enos Salsich are now engaged in building a new dam across Rock River, a few rods below Main Street bridge, in place of the one that was carried away some six weeks ago by the great flood. The new structure will be built in such a way as to make it strong and permanent, and capable of resisting any amount of pressure that will ever be made upon it by any accumulation of water that is likely to flow over it. When completed it will furnish a splendid and reliable water power, sufficient to carry all the machinery that is now located on the river, and as much more as it may be profitable to put in operation. A large number of men are now employed on the work, the object being to get the structure done as soon as possible, so that the mills now standing idle may once more be set in motion. The two grist mills that depend on this power for water are among the largest and best in the state. Both are being thoroughly overhauled and repaired, and will be put into the best running order. When driven to their full speed, they are capable of manufacturing daily large quantities of the best quality of flour, and their brands stand among the first class in all markets where they are seen. They give steady employment to a considerable number of men, and their success is a matter of interest to all. WD

1859

09 01 RED MILL UNDERGOING EXTENSIVE REPAIRS

The Red Mill on the west side of the river, carried on by

Messrs. Salsich and the Greens, is now undergoing

extensive repairs and receiving a new run of stone. These

improvements will add largely to the capacity of this heavy milling

establishment to accommodate the large number who daily resort to it with

custom work and also greatly increase its facilities for manufacturing

bread-stuffs. Mr. Enos Salsich is also

doing another good thing in macadamizing that portion of Water Street which

runs from West Avenue (today West Main) to the mills. This timely

improvement will render the establishments down there easily accessible through

every season of the year, and all who may have business to transact can go and

come without being buried in mud and mire, no matter what the

weather. We are glad to see these changes going on, as they indicate

that our business men anticipate busy times ahead. In this

expectation we trust they may not be disappointed. Here is a wide

and inviting field for profitable manufacturing enterprises and it has only

just begun to be occupied. We hope at no distant day to see it more

generally appreciated and made available.

WD

1850s

-- -- CAKES FOR FIRST KINDERGARTEN KIDS

In

the 1850's that outstanding statesman and soldier, Carl

Schurz, settled in our community and came regularly to the mill, driving

in from his hill-top home, the Karlshuegel of today,

on the northern outskirts of the town, taking with him the flour for the little

cakes so eagerly awaited by the children in his wife's kindergarten. This was the first school of its kind to be

established and maintained in the United States. Derived

from the booklet "The

Globe Milling Company, Watertown, Wisconsin, 1845-1945."

1860

07 19 ADDITION TO RED MILL

The Red Mill, on the west side of the river, is among the

best flouring establishments in this state. Since it has been owned

by Mr. Enos Salsich it has been much improved both in

machinery and its capacity to do work. He is now making a large

addition to the south end of the main building, which will not only be a great

convenience but add greatly to the business facilities of the

institution. The flour that goes from this mill has always been

regarded as fully equal to the best in the market and brings the highest price,

which is the best possible proof of its superior quality. WD

07 26 V. D. Green & Co. of the Red Mills purchased winter wheat; Salsich pushing forward addition to mill WD

1863

02 26 RED MILL OWNED BY CUNNINGHAM & CARR

Since Messrs. Cunningham & Carr have

taken possession of the Red Mill on the west side of the river they have

thoroughly overhauled and repaired the whole establishment, refitted the old

machinery, added much that is new, and put all in the best running order. They now manufacture a quality of flour so

fine and pure that their brand stands among the first in the state and readily

commands the highest price and the quickest sale. They have all the facilities for doing custom

work and farmers from the country always find their grists

ground and ready at the appointed hour.

They do their work promptly and well, carefully avoiding all causes of

complaint. They have a large and

well-furnished mill and we are glad to learn they are transacting a business

both extensive and successful. The more

such manufacturing establishments we have in our midst, the better it will be

for the community. There ought to be a

far greater portion of the splendid wheat annually raised around us sent off in

the shape of flour than has heretofore been the case. WD

03 19 A BIG DAY’S WORK AT RED MILL

Messrs. Carr & Cunningham, the proprietors of the Red Mill, on

the West side of the river, with one run of stone, turned out from their

establishment one hundred and sixty barrels of extra fine flour last Friday in

the space of twenty-two hours. We call

that a magnificent day’s work and we hope they will do many more such. We wish more of our splendid wheat could be

made into flour and sent to the Eastern markets in that shape. The more of our products we manufacture here

the better it is for the whole community.

Home industry is the source of home prosperity. WD

1870

12 28 THE EMPIRE MILL AND ITS CONTENTS

DESTROYED. One of the most

serious calamities that ever befell our city occurred on the night of Wednesday

last, the 28th of Dec. 1870, by the total destruction by fire of the

Empire Flouring Mills, on the west side of the river, owned by George Smith,

Esq., together with its contents, including a large amount of flour and wheat.

The fire broke

out at about nine o'clock, and appeared to have originated on the 2nd floor,

although nothing definite on this point is known. Those first in the building were so stifled

and

suffocated with smoke that they were unable to do more than take a few books,

papers and $400 in money from the safe, and soon the flames burst forth in all

their fury.

The alarm being

sounded the Engine and Hook and Ladder Companies

were promptly on hand, ready to render all the assistance in their power.

It was not many

minutes before the fire had gained such an advantage that all attempts at saving

the building seemed futile, and the efforts of the firemen and bystanders were

next directed to the preservation of the surrounding property.

Immediately on the

north side, and within 40 feet of the mill is situated the Woolen Factory, owned by Mr. Daniel

Jones, and containing valuable machinery and stock, and adjoining this building

is the Sash and Door Manufactory of Mr. G. B. Lewis. As a precautionary measure against fire, Mr.

Smith had surrounded his mill, which was a frame building, with brick walls,

and the saving of the Woolen Factory is mainly due to this fore thought on the

part of Mr. Smith for all endeavors to save this building would have been

unavailing had not the north wall of the mill stood as a barricade between the

intense heat and angry flames and the Woolen Factory.

Nevertheless it

was only through the most heroic efforts of the firemen and others that fire

was confined to its original limits and thus a most disastrous conflagration

prevented. The rising flames from the

burning mill lighted up the heavens in such a manner as to be seen by persons

living a distance of 25 miles, creating a sight at once grand and awful, and

the excitement throughout the city became intense, hundreds of our citizens

coming out to witness the terrible ravages of fire.

While the flames

were at the height of their fury, there occurred an appalling accident, which

carried dismay and consternation to all hearts.

Mr. Nathaniel Blanchard, while on the roof

off his own mill, on the opposite side of the river, endeavoring to protect it

from flying cinders, lost his foot-hold and fell a distance of about forty

feet, striking on the ice, breaking both legs and arms, and otherwise injuring

him so fatally, that he survived only twelve hours.

In the meantime the flames

made rapid progress and the devouring element held full sway over the doomed

building. The brick wall, however, still

stood the severe strain and test, and the question as to the safety and

destruction of the Woolen Mill, hung, as it were, in the balance, and could

only be determined by the manner in which the wall nearest the building would

fall. At length the period arrived which

was to decide the fate of some $20,000 worth of property, down came the immense

wall, which had stood as a sentinel, with an immense crash. A loud shout rang from the vast throng when

it was seen that the wall fell favorably, the Woolen Mill was saved and the

further destruction of property saved.

The night was still and cold, with scarcely a breath of air stirring--a most favorable circumstance for the safety of the adjoining property, for had a high wind been blowing the amount of property burned would have been immense.

Mr. Lewis prepared for the worst by removing the stock from his Door and Sash Manufactory, meeting with some loss by its removal. D. Jones & Co. moved most of their removal stock from the Woolen Factory, but luckily did not attempt to take from the building any machinery. Their loss is but slight considering the great jeopardy their property was placed in.

Together with the mill and machinery there were destroyed between 9,000 and 6,000 bushels of wheat, and 45 barrels of flour, making a total loss of about $50,000, covered by an insurance of $21,500, distributed as follows: $6,000 on mill; $10,500 on machinery; $5,000 on stock.

This loss falls with

great severity on Mr. Smith, and would crush and dishearten most men. It is barely six months since his fine

residence and all his valuable contents were totally destroyed by the fire

fiend which has just layed low his flouring

mill. The loss of his extensive mill

cannot be viewed in any other light than that of a great public calamity, the

effects of which are felt by our entire community. Wttn

Rep, 01 04 1871

1877 GLOBE MILL TELEPHONE No. 1 / FIRST PHONE INSTALLED in Watertown

In 1877 the first telephone in service in Watertown was

installed in the office of the Globe Milling Co. by the late John B. May,

prominent photographer of Watertown, who conducted his business on the site of

the present Masonic temple and he resided

in the home now occupied by Owen T. Hughes, [312] Washington Street. Mr. May put in telephone service in Watertown

at his own expense, and operated it for nine years, and in 1884 he disposed of

it to the Wisconsin Telephone Co. WG, 12 29 1932.

The Globe Mill Co.'s

phone number, No. 1, was still maintained as late as 1957, in a City Directory ad

c.1870s

-- -- GLOBE MILL FIRST TO SOUND ALARM OF FIRE

The hum of machinery in a country mill

gave off soft music in the small hours of the night, bringing assurance to the

timid that men were awake and about their business. Its low pitched whistle was

the FIRST TO SOUND THE ALARM OF FIRE, summoning the volunteers to their duties.

It stood sentinel over the sleeping town. "The Globe Milling Company, Watertown, Wisconsin,

1845-1945."

1880c EMPIRE MILL

Original Empire Mill burned down in 1870 and

rebuilt. Became part of Globe Mill in

1891

Original Empire Mill burned down in 1870 and

rebuilt. Became part of Globe Mill in

1891

1887

08 12 LARGE NEW BOILER FOR

THE GLOBE MILL

A large new boiler,

which was drawn through our streets last Friday and placed in the Globe Milling

Co.'s mill on the west side, was manufactured at the foundry

and machine shops of Ernest Kunert. It is a fine piece of work and reflects much

credit on its manufacturer. Its

dimensions are six feet in diameter, 16 feet long, with 50 flues and a steam

dome 36x48 inches.

It is as large a boiler

as has ever been manufactured in the state and cost $1.450.

With more capital at Mr. Kunert's back, there is no reason why he could not be made

one of the best boiler manufacturing establishments in the state, and some

effort to this effect should be made.

03 16 ANOTHER STORY ADDED TO EMPIRE MILL

Next week the Globe Milling Company will begin to

build another story on their Empire Mill, west side. New machinery will be placed in the two upper

stories and centrifugal and rounding bolting reels will be added. With this new machinery they will be able to

turn out even better flour than the celebrated brands they are now

manufacturing, and the capacity of this mill will be increased to 300 barrels a

day. WG

1890

01 29 GLOBE MILL MAY RELOCATE

It is not very pleasant to contemplate that any of our establishments shall be taken from us, much less the Globe Milling Company should be one of them. There is some talk of this kind, unpleasant as it may sound. H. Mulberger and Gus. May have returned from a trip to Ashland and West Superior. At the former place they met with all the encouragement they could ask in case they made up their minds to remove the plant. A large-sized site and a bonus of $5,500 in money were offered them if they would start a mill of the capacity they require. The shipping facilities both by rail and water were also found satisfactory. The matter of the Globe Mill being removed from here will be decided within a short time. To remain here it would be necessary for Globe Milling to add another story to their mill and fit it up entirely with new machinery, at a cost of not less than $15,000. . . . WR

02 07 GLOBE MILL WILL REMAIN

The people of Watertown hail with delight the information that the Globe Mill Is to be retained here, and that a 20-foot addition is to be added on top. Between $10,000 and $15,000 will be expended in improvements, and when completed, Watertown will have one of the very best mills in the northwest. The proprietors deserve much credit for their enterprise in enlarging their mill, and for deciding to retain it here, notwithstanding the fine encouragement given them to remove to other quarters. WG

07 23 UPGRADE OF PLANT COMPLETED

12 19 W. J. LEE WINDOW DISPLAY

That winter scene in W.J. Lee's window is admired daily by hundreds of people. The "Globe Mill” and the mill pond, the castle and windmill, all bedecked with "snow;” and the coasting on the hill are so realistic that one almost forgets for a moment that the scene is not a natural one. Mr. Lee has shown himself quite an artist in this arrangement. WG

1894

1894

12 26 MOVING EMPIRE MILL SMOKE STACK

Edward May

has a force of men engaged in removing the smoke stack on the Empire Mill from

the present to a new location, so as to connect with an extra boiler which has

lately been put in the mill. It is quite

an engineering feat, but Ed. seems to be equal to it. WR

1895

01 09 EMPIRE MILL FIRE

A fire was discovered at noon yesterday in

the Empire Mill of the Globe Milling company, and for a time it was feared the

company would suffer a loss like that sustained last August in the destruction

of the Globe mill. But the alarm was hastily

given and the firemen were at work without delay, subduing the flames before

any headway had been gained. Several

streams of water were at work, both on the outside and inside of the mill, and

the chances were altogether against the fire spreading. The flames were located in the bran room,

connected with which is a conveyor from the elevator. One of the buckets of this conveyor had in

some manner got out of running order, thereby stopping the movement of the

belting, and the continued revolving of the drive pulley – which was directly

at the head of the conveyor, where the grain was discharged to the bran room

produced a friction on the belting which in time burned the latter. The communication of the flames to the bran

followed, the fact being discovered by William Wurtzler

and others of the mill hands just as they were about to leave for dinner.

Owing to

alterations being made in the flouring department, the mill was running only

its feed department. No material loss

was occasioned by the fire, the principal damage being done by the large amount

of water poured into the building. This affected the machinery and other

contents considerably. It is thought the

loss will be at least $1,500. The property

is amply insured. It was a narrow escape

from a most serious conflagration, and everybody is thankful that if was no

worse. The company will be delayed some

by the cleaning-up process. WR

01 16 The loss

occasioned by the blaze at the Empire mill last Tuesday was not nearly as large

as first reported. It was adjusted by

the insurance company at about $200. WR

03 15 HARD WHEAT

PATENT FLOUR

Now is the time to buy your

flour. The Globe Milling Co. will sell

you a 49-pound sack of strictly hard wheat Patent flour for 90c., delivered to

any part of the city. WG

1898

VIEW FROM MAIN ST BRIDGE

05 25 QUOTATION FOR LARGE ORDER OF RYE FLOUR

Some large

orders for breadstuffs are being placed in these times of war at high

prices. The Globe Milling company has

given quotations to a Pittsburgh firm on a 6,000-barrel lot of rye flour, the

magnitude of which may be realized when it is known that the company’s plant

would require five weeks to mill the order.

WR

1899

05 16 IMPROVEMENT AND ENLARGEMENT OF MILL CAPACITY

The Globe

Milling Company has now received all the machinery which is necessary for the improvement

and enlargement of its mill capacity.

The work of setting up will proceed as soon as the water power

ceases. The flour and feed warehouse

which is being built will soon be ready for occupancy if the weather continues

favorable. WR

1900

02 13 NEW STEAM PLANT

The Globe

Milling Co., manufacturers of the celebrated White Daisy and other well-known

brands of flour, have awarded the Twin City Iron Works of Minneapolis the

contract for a new steam plant. The

specifications called for the 14x24x36 tandem compound condensing Corliss

engine. The engine is to be completed

about May 15 and when installed this concern will not only possess the finest

steam plant in this locality, but will have as economical a power plant as

there is in the state. It will be the

first compound condensing engine in the city.

The sharp competition in the milling industry compels all mills to adopt

the most economical methods, which was the incentive for the company to go to

this extensive outlay. WR

c.1900

1902

1903

09 11 GLOBE MILL IN FULL OPERATION

The

improvements, under construction at the Globe Mill in Water Street for some

time, have been completed and the mill is now in full operation, turning out

its famous "White Daisy" and other brands of flour and other products

manufactured by it. New machinery of the

very latest kind for milling purposes has been added, and the mill is now one

of the very best equipped in Wisconsin.

At present the mill is being operated entirely by steam, but when the

remodeling of its water power plant has been completed, water power will also be utilized. The Globe Milling Co.'s, product is very

popular in Watertown and vicinity, and the local trade is quite extensive. Some of the largest jobbers and bakeries in

the eastern and central states are also supplied with the product of this mill,

New York City especially taking a large quantity of the flour

manufactured. Over $250,000 in wages has

been paid out by this company in

Watertown since its incorporation 18 years ago, hence it will by seen that it is an industry that certainly

deserves encouragement here, for it is one of our most important

commercial interests. WG

1905

Alex Hardie

1956 painting of Globe Mill in 1905,

left; G.B. Lewis center.

Alex Hardie

1956 painting of Globe Mill in 1905,

left; G.B. Lewis center.

Fire destroyed the Lewis Water St building in June of 1909.

Globe Mill and dam, left; Alex Hardie 1905 picture, used in

his painting, 1956

Globe Mill and dam, left; Alex Hardie 1905 picture, used in

his painting, 1956

1915 Ad

1915

04 29 MULBERGER STRIKES AT TRADITIONAL DOINGS OF

SHARP HORSE TRADERS

The Milwaukee

Journal of April 20th, printed a good picture of Senator Mulberger and a writeup, under the heading of “Mulberger Strikes at Traditional Doings of Sharp Horse

Traders,” as follows:

“Senator Charles

Mulberger, Watertown, who represents the Democratic

Thirty-third district, was born, reared, educated and elected in his home

town. He has the reputation of being a

good business man, who is much interested in city government. So he was placed on the Committee on

Corporations where he would have opportunity to exercise his special training.

“Mulberger tends

strictly to business, but he does it without making many speeches or

introducing many bills. One of the bills

he has introduced, however, may cause all the David Harums

and other hoss-traders to organize a lobby, because it includes livestock in

the category of things which it is forbidden to fraudulently advertise.

Mulberger graduated from the Watertown high school and the

university law school and has been manager

of the Globe Milling Co. for eighteen years. He was alderman four years, and president of

the fire and police commission the same period.” WG

1917

05 02 GLOBE

MILLING CO. SELLS LOCAL PLANT

PHILADELPHIA CORPORATION TO TAKE POSSESSION OF FLOUR MILLS ON JUNE 1.

Mayor Mulberger Will Retire as Manager After Twenty-Two Years of Service.

The Globe Milling company of Watertown whose

flour mills are located in Water Street has disposed of the entire plant to

Shane Bros. & Wilson Cos. of Philadelphia, one of the big eastern milling

concerns. The price agreement has not

been made public. The milling company

has been one of the widest known in this section of Wisconsin and has been in

business many years. The officers

are: President, W. D. Sproesser; vice president, Charles Mulberger;

secretary, George W. Manschott; treasurer, Henry Mulberger. Mrs.

Mathilda Mulberger is one of the stockholders. It is said that Mr. Manschott

will be retained in the employ of the new corporation and it is probable that

the present office force will not be disturbed.

Mayor Mulberger has

been closely identified with the business for twenty-two years and while

retiring from the firm will still continue a resident of Watertown. He is the present state senator from this

district and will probably take a rest from business cares for awhile.

A Pioneer Mill

The Globe mill has a history far back. In 1848 a mill was built known as the Emerald

mill and later the Empire mill. It was

built by Fay & Cramer of Milwaukee.

It was later leased to Potter & Ford and Enos Salsich,

the latter purchasing the plant which was later sold to the Bank of

Watertown. George Smith and Dr. Hoyt

purchased the mill. Smith later being

the sole owner and during his owner ship the mill was destroyed by fire. This was in 1870. He rebuilt it and later sold it to the First

National Bank, from whom Christian May purchased it and in 1874 a consolidation

of interests took place between Miller & Quentmeyer

and Mr. May, the firm operating three mills on both sides of the river.

The present Globe Milling company was the

outgrowth of a business which was a pioneer in Watertown and its business in

the last twenty years has developed fast.

A rye flour mill was combined with the regular mill several years ago

and the product of both found a ready sale in the markets of the world. The

Watertown Weekly Leader, May

02, 1917

1922

In front of building is the first motorized vehicle used by the firm for deliveries. Prior to 1922 the deliveries were made by horse and wagon.

Print from which above image was derived.

Do you see that little hut on the top of the mill? My Dad got that when they tore down the top of the mill. He used it for our shed . . . . Boy I remember it like it was yesterday – Wayne G Loeffler, 2014 contribution.

1930

WALTER GRAMDORF

Walter Gramdorf

(wife Elsie) was assistant foreman at Globe Milling

Walter Gramdorf

(wife Elsie) was assistant foreman at Globe Milling

![]()

1930 Watertown City Directory

1932

-- -- PRODUCTION EMPLOYEES / GLOBE RYE MILL

Mautner,

John (Jack), H. O. Hoffmann, Joe Berg, William Haberman, Frank T Weber, John

(Joe) Oestreich, Ted Will, Walter Gramdorf,

Herman Boltz, Fred Mallach, August Fluegel, Gus Haack, Joe Zoeller, Edward Kasten, Joe Wimmer, Jerome Wagner, Ronnie Mautner, Emmanuel (Gus) Haznow,

1936

07 04 FLOAT IN CENTENNIAL PARADE

1930s

THE GLOBE MILL HOME / Home of president Kenneth Burns

1945

-- -- ED KASTEN, feed grinder

-- -- 1845-1945 CENTENNIAL BOOKLET 14-pg pdf file

-- -- COOPERATION

WITH FARMING COMMUNITY

We are

active in helping to promote and support a Farmers' Institute held in Watertown

each winter. Before the war this was a

two-day affair, but during the war it has been restricted to one day. Faculty members of the University Farm

School, as well as nationally known speakers from industries, discuss farmers'

problems of management and feeding. The

usual attendance is one thousand farmers and their wives, and it is the largest

institute of its kind in the state.

We cooperate with the farming community in securing soil analysis

through the University laboratories, together with their recommendations for

fertilizers, of which we distribute many car loads annually. We arrange for the planting of small adjacent

lots of land for testing different varieties of seeds, recording their

development and output. It may seem a

far cry from baby chicks to milling but we sell up to eighty thousand each

spring, and these together with countless thousands hatched on the farm consume

many tons of feed in their development to laying hens and roasters. The

manufacture and sale of these feeds is strictly within the province of a

country mill. As an additional service

we conduct a Poultry Health Clinic where post mortems or postings are held to

determine causes for flock epidemics or unsatisfactory progress. Remedies are

available on the recommendations of our own men trained for the purpose. We operate two retail branches within a

radius of fifteen miles of the mill, at which are offered all the services and

supplies available at our retail headquarters.

In general, it is our policy to do everything in our power to promote a

more prosperous farming community, a prosperity in which we share.

1952-53

GLOBE MILL BOWLING TEAM

William Hoeft, Arch Grinde, Robert Oestreich

Albert Schlueter, Arnold Reuschel, Walter Geise

1956

06 21 PURCHASE OF HUBBLETON FEED MILL

Announcement

has been made by S. C. Northrop, president of the Globe Milling Company, of the

purchase of the feed mill of the Auer-Braun Lumber Company at Hubbleton. The Globe

Milling Company will take possession July 1 and will operate the business as

the “Hubbleton Feed Mill.” The Auer-Braun Lumber Company will continue

operation of its lumber and coal divisions as in the past. The Hubbleton feed

mill will continue to grind feed and serve the needs of the farmers of the

community and will handle a complete line of poultry, dairy and hog feeds as

well as fertilizers and seeds.

1957

07 24 Ray Kaercher, vice president of the Globe Milling Company, has been selected to direct the Red Feather Drive in Watertown in October. Mr. Kaercher is now lining up division leaders and laying plans for the coming drive. In the 1956 drive Mr. Kaercher served as associate drive chairman working with industry and payroll deduction. WDT

1958

07 02 ROCK

RIVER DIVERSION PROPOSED

City officials and representatives of the Globe

Milling Co., and the Jaeger Milling Co., are going to make a study of what

effect a proposed Rock River water diversion will have on the city and the

milling concerns. The proposed diversion

is to be the subject of a hearing at the City Hall on July 28 by the State

Public Service Commission of Wisconsin.

Curt Kanow, Ixonia farmer, has filed a

petition with the commission for permission to divert up to 1,000 gallons per

minute each year from May to Oct. 1 to irrigate 60 acres of land on his

farm. WDT

1963

06 15 The

Durant Manufacturing Co., through its Milwaukee office, announced today that it

has found its most satisfied customer right here in Watertown where Durant

operates a plant. The customer is the Globe Milling Co. In 1879, W. N. Durant conceived the idea of a

mechanical counting device to tally bags of flour at the Milwaukee Rolling

Mills. Thirty-seven years before that,

in 1842, one of Watertown’s very first industries was established. Recently representatives of these two

companies, now only blocks apart in Watertown, had reason to join together to

look back through some of those years.

Durant manufactures counting and controlling instruments and Globe is a

producer of rye flour. The occasion was

brought about by the discovery that several early model Durant counters were

still being used at the Globe Milling Co. Mill. WDT

1966

07 26 S. C.

Northrop, 506 South Fifth Street, board chairman of the Globe Milling Co.,

Watertown, was honored for his 47 years of service with the firm at a dinner

held Wednesday night at the Green Bowl.

Officers and directors of the company, plus managers of the five company

branches attended with their wives. Mr.

Northrop was presented with a valuable set of stereo recordings. President Ray H. Kaercher

presided and lauded Mr. Northrop for his many years of leadership with the

company. Mr. Northrop went to a

consulting basis as of June 1 this year to be succeeded by Mr. Kaercher. Mr.

Northrop has been a civic leader locally, being active in Rotary, the American

Legion, and served on the school board for 12 years with two years as

president. He has also been an alderman here.

WDT

1967

01 14 REMODELING PROJECT COMPLETED

The Globe Milling Company will hold a “Grand

Opening” on Friday, Jan. 20, to celebrate the completion of its recent modern

remodeling project. In order to better

serve their customers, the mill has installed two platform hoists, which put an

end to shoveling of grain for shelling or grinding. The company has also installed a new large

corn sheller and elevator leg, which, together with a large dump pit, speeds up

shelling. With this new shelling setup,

customers can either have their corn shelled and ground or take some home

either in sacks or bulk. A new five-ton

mixer also gives greater efficient mixing together while speeding up in

service. A large handy bulk-out bin

gives the customer a choice of taking the mixed feed home in bulk or in sacks.

Everyone interested in this new type of service is invited to attend the grand

opening and look it over. WDT

1969

02 05 FIRE AT

THE GLOBE MILL

An alarm was received at the Watertown Fire Department at 6:08 a.m. with all firemen and auxiliary firemen called to combat the blaze.

One fireman, Captain Harold E. Hell, was taken to the Watertown Memorial Hospital for back X-rays after he slipped and fell on a stairway.

Gordon Madsen, manager of Globe Milling, stated the malt flour department is not operational. He estimated that this portion of the plant would not be in operation for a month or possibly longer. The feed department was not damage and operations will continue. Madsen stated, “We would have had a total loss without the sprinkler system.”

The power belts running much of the equipment were ruined, and much of the equipment cannot be replaced, it must be repaired. Water damage was high and a great deal of cleanup work needs to be done because the water mixed with the flour in the building, making a paste.

1970

July CITY'S

OLDEST BUSINESS UNDER NEW OWNERSHIP

A to Z FARM CENTER, INC

President and general manager is Herbert Johnson of Cambridge. Attorney Donald Rumpf, also of Cambridge, is the secretary-treasurer.

Globe Milling Company is the oldest business in Watertown. It is now in its 125th year.

President of Globe Milling Company was Edward G. Broenniman, Chicago. Allen Rieselbach of Milwaukee had been secretary-treasurer. Gordon Madsen was executive vice president; and Joseph Wimmer was a vice president in charge of flour production.

An important operation of the mill is the manufacturer of flour from barley malt. The firm will continue to buy corn and oats from local farmers, and sell the processed product at retail.

Grind and mix will continue to be offered, and there will be pick-up and delivery in feed along with fertilizers, seed, animal health products and farm supplies. Purina feeds will continue to be sold. To this Wayne feeds have been added.

Until a fire at Globe Milling Company on Feb. 5, 1969, rye flour was milled. Since the fire, this phase of the operation has been discontinued.

The purchase included the acquisition of mills at Helenville, Hubbleton and Hustisford, which had been owned by Globe Milling Company. The Farmington-Rome mills owned by Globe Milling Company, have been closed.

For many years S. C. Northrop was president and in charge of the mill. Following his retirement, the late Ray Kaercher was the manager. Following his death, Gordon Madsen managed the mill. Kenneth L. Burns preceded Northrop in operating the mill. Madsen has been employed by the new firm in an accounting capacity. Wimmer continues in charge of flour production.

07 07 A to Z FARM CENTER ACQUIRED GLOBE MILLING Co.

1990s

1993

11 12 FUTURE POTENTIAL SEEN FOR GLOBE MILL

Most people traveling South Water Street probably don’t visualize the street as a possible draw for visitors from outside the area. In fact, some would say the old mill and other industrial-looking structures are an eyesore. But, local businessman Larry Mistele has looked past the unsightly facades to see the potential in the historic buildings. “I think the mill will become a destination point for southeastern Wisconsin,” he said. “That’s going to be a place for a day trip.” Mistele, who is joined by various investors, is planning a major facelift for the South Water Street area. He already has renovated the old Beals and Torrey Shoe Factory into the Mill Race Terrace apartment building and now he has plans to convert other old buildings — including the feed mill — on the street for retail purposes.

1998

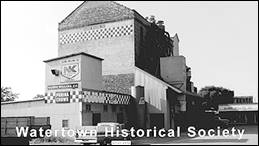

Mill was severely damaged by heavy winds in 1998 and what remained of the structure was destroyed by a fire in 2001.

1999

07 09 GLOBE MILL RETAINING WALL

In its day, the old mill on South Water Street was the hub of activity for a farming community. Hundreds of gears turned as grain was pulverized into flour, generated by power from the Rock River. The fate of the historic landmark was sealed late last year when 70 mph winds whipped through the area, taking with them an entire wall of brick along the east side of the mill facing the river. What was a central supporting wall of the mill is now a massive pile on the shore. Owner Larry Mistele, who renovated a former lumber mill to create The Market across the street, said the loss of the wall made the building unsafe. Heavy equipment was on site this morning to tear down the old mill. WDT

2001

05 03 130-YEAR-OLD MILL BUILDING BURNS

![]() Image

Portfolio Chapter on

the fire

Image

Portfolio Chapter on

the fire

2003 ROC building, 321 S Water. The ROC was in the Water Street building from Dec 2003 to Oct, 2009.

2007

11 22 POTENTIAL DEVELOPMENT AT FORMER MILL

A group of developers met with city officials Tuesday during a committee of the whole meeting to discuss a potential $31 million development at the former Empire Globe property on South Water Street that includes townhomes, apartments and retail space. According to Rick Andritsch, vice president of VJS Construction Services, the first phase of the project would include a retail building with apartments on the upper floors on the north side of the property and townhomes on the south end of the property. Andritsch said the north building would have 34 underground parking stalls and about 11,000 square feet of retail space on the first floor. The three stories above the first floor would have 45 residential units. The next building to the south would have about 14,600 square feet of retail space on the first floor and 48 living units on the upper floors, Andritsch said. The structure just south of the dam would have 43 underground parking stalls and 52 living units. WDT

12 19 RIVER MILL RESIDENCES

Approval of conceptual plans for the redevelopment of the former Empire Globe property as River Mill Residences. Total project will encompass the area along the west bank of the Rock River just north of the Mill Race Terrace Apartment building and will go north and include the upper and lower city parking lots on the east side of Water Street from the east end of Emmet Street north to include much of the city parking lots. WDT

River Mill Residences images from 2012, WHS_006, 420a, 420c, 420e.

12 20 RIVER MILL INVESTMENTS PLANS APPROVED

The Watertown Common Council Tuesday endorsed a

resolution approving the conceptual plans submitted by River Mill Investments

LLC for the redevelopment of the former Empire Globe property on South Water

Street. River Mill Investments is in the

process of considering the property for a mixed use of development and the city

has previously entered an option agreement with the developing group for the

purchase of the parcel. The first phase

of the project will consist of two structures, one at the north end of the

parcel and five two-story townhomes at the south end. The building to the north of the property

will have about 11,275 feet of commercial space and 75 units for mixed income

senior housing.

2008

03 07 RIVER MILL DEVELOPMENT CONCEPTUAL PLANS

Preliminary conceptual plans for the proposed $30 million River Mill development along South Water Street were reviewed Monday afternoon by the Watertown Site Plan Review Committee. The total project will encompass the area along the west bank of the Rock River just north of the Mill Race Terrace Apartment building and will go north and include the upper and lower city parking lots on the east side of South Water Street. The first phase of the project will consist of two structures, one at the north end of the parcel and five two-story townhomes at the south end. The building on the north end of the property will have 54 units for mixed income senior housing and space for commercial purposes. WDT

03 27 PROPOSED DEVELOPMENT

A proposed development on South Water Street

will result in a new home for a number of senior citizens, but it also means a

local meeting place for teenagers will have to find a new location. CommonBond

Properties and Spectrum Development Group are currently in the process of

looking to build a 54-unit senior housing complex and five town homes on the

east side of South Water Street just south of the lower dam, which is the

current site of the Watertown Recreation and Outreach Center for Youth. The ROC would be razed

once construction on the apartments and town homes begins. The Rev. Timothy Mueller, director of the

ROC, said he and other community members are currently looking for a new

building in the city that the youth center could call its future home.

Cross References:

Ira O. Howe was a miller, 1881

Nicholas Bickner employee

Sanford’s barrels are generally used by our millers

Joseph

Wimmer was the Miller at Globe Milling Company on Water

St. for many years. I was a secretary in the office across the

street. He would bring us

samples of the flour he milled, so we could send them. I always enjoyed talking to him. He also started working some hours at Neitzels at that time. - Faye Petig

![]()

History of Watertown,

Wisconsin